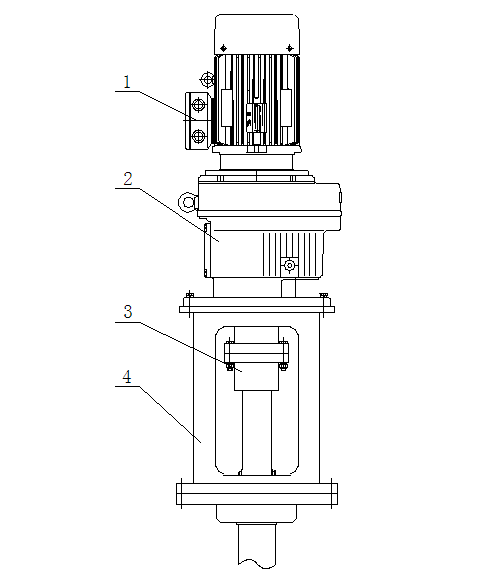

Industrial agitator drive unit is provided with heavy duty lantern support, bearing housing and different sealing arrangement like stuffing box, mechanical seal etc. Standard gearbox and motors can be provided in flameproof constructions.

Variety of impellers offered like axial and radial for different property of liquid and process requirement.

Vertical agitators

CO-AXIAL AGITATOR

SIDE ENTRY AGITATOR