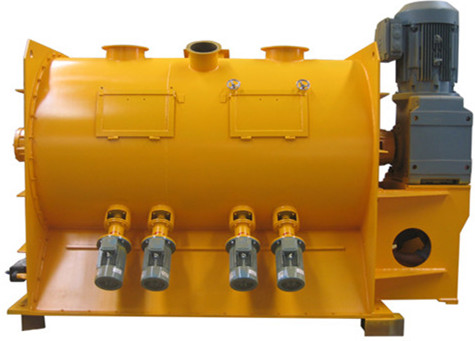

Plough Shear Mixer (also named plough share mixer, plow mixer, plough mixer) consists of a cylindrical drum containing plough shaped mixing elements that are mounted on a horizontal shaft. It creates a mechanical fluidized bed mixing action. The mixing tools project and hurl material away from the wall into free space in a crisscross direction, and inversely back again. The plow separates and lifts the product into three-dimensional motion, while the number and arrangement of the tools insure agitation back and forth along the length of the vessel. When required, the mix action is assisted by high speed chopper devices–independent high-speed motors with customized blades for adding shear to the product mix.

Advantages of Plough Shear Mixer

- High Speed and Homogenous Mixing

- Wide Range of Applications

- Short Mixing Time

- Easy to Clean

- Avoid Agglomeration

Standard Features of Plough Shear Mixer

- Capacity range from 100-30000L

- Mild Steel/Stainless Steel construction

- One end welded and one end bolted

- Normal Temperature and Pressure inside mixer

- Gear Reducer Motor

- Gland Packing Seal + Air Purge Seal

- Pneumatic Operated Outlet Valve

Application of Plough Mixer

The batch plough shear mixer is the most versatile mixer type available with an extensive range of applications:

Dry powder mixing

- Paste mixing

- Mixing of wet slurries

- Wet granulation

- Liquid coating of powders and granules

- Fat and oil incorporation

- Vacuum drying

Processed Material:

- Foods

- Starch

- Flavoring

- Coffee

- Chocolate

- Nutraceuticals

- Cosmetic

- Pharmaceuticals

- Detergent

- Soaps

- Metal Powders

- Minerals

- Friction Material

- Ceramics

- Agricultural Chemicals

- Cement and Sand

- Carbon black

- Fire retardants

- Talcum powders

Features of Plough Mixer

- Multiple design for plough shovel (plough with teeth, end scraper)

- Petal type chopper, knife type chopper

- Vacuum/Pressure inside mixer

- Heating/Cooling Jacket for mixer

- Spraying Nozzle for liquid

- Various Outlet Valve depend on customer’s process requirement

- Heavy-duty drive unit

- Explosion-proof for electricity

- Electrical Control Panel system

- GMP manufacturing

- Teflon Coating for material contact part

- Abrasion resistance treatment

- Other Special Customize Design

Technical Specifications of Plough share Mixer

| Model | Nominal Volume | Working Volume | Speed (RPM) | Motor Power |

|---|---|---|---|---|

| PM-0.1 | 100L | 40-60L | 101rpm (shaft) 1440rpm (chopper) |

3KW 1.5KW x 2 |

| PM-0.3 | 300L | 120-180L | 85rpm (shaft) 1440rpm (chopper) |

4KW 1.5KW x 2 |

| PM-0.5 | 500L | 200-300L | 85rpm (shaft) 1440rpm(chopper) |

7.5KW 1.5KW x 2 |

| PM-1 | 1000L | 400-600L | 85rpm (shaft) 1440rpm (chopper) |

11KW 4KW x 2 |

| PM-1.5 | 1500L | 600-900L | 85rpm (shaft) 1440rpm (chopper) |

15KW 4KW x 2 |

| PM-2 | 2000L | 800-1200L | 85rpm (shaft) 1440rpm (chopper) |

18.5KW 4KW x 3 |

| PM-3 | 3000L | 1200-1800L | 57rpm (shaft) 1440rpm (chopper) |

18.5KW 4KW x 3 |

| PM-4 | 4000L | 1600-2400L | 57rpm (shaft) 1440rpm (chopper) |

22KW 4KW x 4 |

| PM-6 | 6000L | 2400-3600L | 57rpm (shaft) 1440rpm (chopper) |

30KW 4KW x 4 |

| PM-8 | 8000L | 3200-4800L | 42rpm (shaft) 1440rpm (chopper) |

45KW 4KW x 4 |

| PM-10 | 10000L | 4000-6000L | 33rpm (shaft) 1440rpm (chopper) |

55KW 5.5KW x 5 |

| PM-12 | 12000L | 4800-7200L | 30rpm (shaft) 1440rpm (chopper) |

55KW 5.5KW x 5 |

| PM-15 | 15000L | 6000-9000L | 30rpm (shaft) 1440rpm (chopper) |

75KW 5.5KW x 5 |

| PM-20 | 20000L | 8000-12000L | 30rpm (shaft) 1440rpm (chopper) |

90KW 5.5KW x 5 |