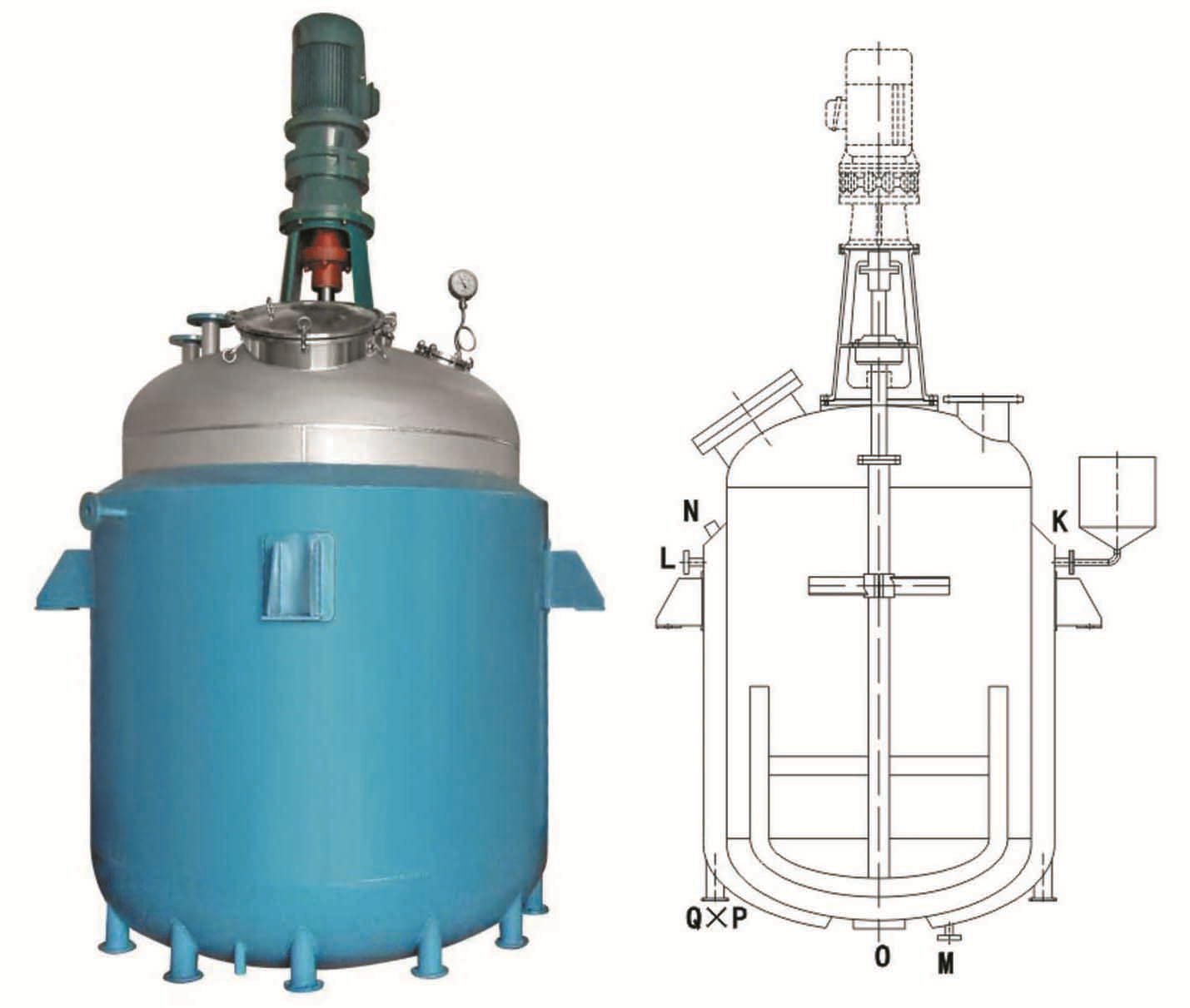

Stainless Steel Reactor Vessel

Pressure vessel/reactor vessel

Pressure vessel/reactor vessel is a closed container designed to hold liquids, solids, gases, or a combination of either of the three phases at a pressure substantially different from the ambient pressure. Pressure vessels can theoretically be almost any shape, but shapes made of sections of spheres, cylinders, and cones are usually employed. A common design is a cylinder with end caps called heads. Head shapes are frequently either hemispherical or dished (torispherical ). More complicated shapes have historically been much harder to analyze for safe operation and are usually far more difficult to construct. Reactors/pressure vessels may have different combinations based on the application they are being used. Some may have jackets, some will have limpets with simple inlet and outlet, and some will have limpets with multiple inlets and outlets, sometimes with internal coils and sometimes with a combination of jacket/limpet and internal coil.

Our capability extends to the design and manufacturing of various types of pressure vessels custom made for a wide range of applications. Our product range includes air receivers, surge tanks, accumulators, blowdown tanks, flash tanks, expansion tanks, pressure vessels, condensate pots and more.

Years of expertise and skills have enabled our company to reach new heights of success in the markets of pressure vessels. We have been catering to the demands of vessels in varied industries for different applications. We can offer these vessels in a variety of material of construction like CS, SS304, SS316, low-alloy steel and non-ferrous metals etc. We have the capability and experience of handling a variety of MOCs and accordingly, we have qualified necessary WPS, PQR. Steel is purchased directly from renowned manufacturers to ensure reliability. For small quantities and quicker deliveries, we also purchase steel from our reliable and well-established traders and stockiest, who can deliver plates of approved and recognised steel manufacturers, in a wide range of thickness with a minimum lead time.

Chemical Processing Jacketed Reactor Vessel

Description of Reactor Vessel

We are recognized firm engaged in manufacturing extremely efficient Reactor Vessel that is the central component of the reactor coolant system and which is sturdily steel constructed by the skilled professionals of our company. The Reactor Vessels designed and developed by us are widely used in commercial nuclear power plant, pharmaceutical industries, chemical plants, etc.

Reaction vessels are at the heart of a chemical plant. They are where the chemical Changes and reactions take place. Powders or liquids may be poured into reaction vessels using large funnels, called hoppers, connected to the top of the vessel.These stainless steel liquid mixing tanks are highly efficient to use with its robust mixing structure for homogeneous mixing of different chemicals and ingredients.

Abster™ Equipmetn is an extremely efficient Reactor Vessel Manufacturer and Supplier company from Ahmadabad, Gujarat, India.

Material of Construction :-

- MS Jacketed – SS304 limpet coil for heating & cooling tested for 5kg/cm²

- Anchor shaft, propeller, turbine will be available

- Chemical cleaning is done internal & external to remove contamination.

- Material can be Carbon steel, mild steel, stainless steel, 304, 304 L, 316, 316 L, 317 L, 904 L.

- Blades with different shapes such as: Paddle Form, Frame Form, Scrapper Form.

Features :-

- High quality

- Durable

- Reliable

- Strong Construction

- Superior Functionality

- Corrosion Resistance

- High Durability

- Easy Installation

Heating way mainly :-

Steam Heating, Thermal Oil Heating, Electric heating etc.

Applications :-

The reactor vessel used in the first commercial nuclear power plant, Fit for pharmacy, chemical industry, dye, resin and food Industry, It can be widely used in Liquid Resin, Rubber, Pesticide, Glue, Dye, Medicines. Food, Pharma, Chemical, Minerals, Guar Gum, Starch, Pigment Colors & etc.

Model size is Available :-

500 ltrs to 20,000 ltrs (Drive HP as per design)