Application of the three roller mill

The three roller mill is the most effective grinding and dispersing equipment for high viscosity materials. It is mainly used for grinding various liquid paints and paste materials such as paints, inks, pigments, plastics, cosmetics, soaps, ceramics and rubber.

Three Roller Mill Working principle:

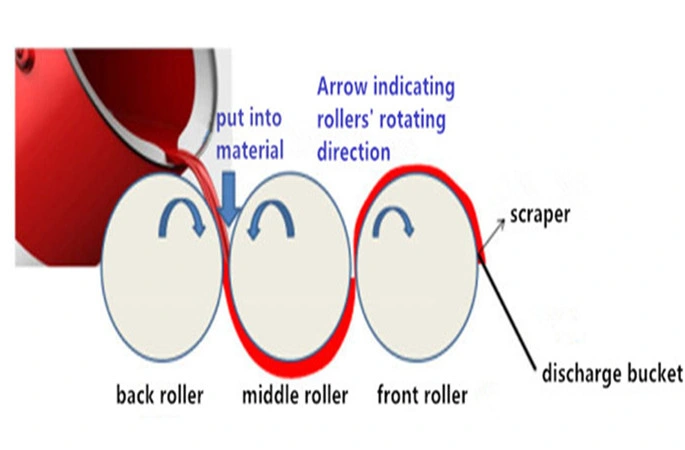

The Triple roller mill has three rollers mounted on an iron frame with the center in a straight line. Can be installed horizontally or slightly tilted. The grinding effect is achieved by mutually pressing the surfaces of the three horizontal rollers and rubbing at different speeds. The steel drum can be hollow and cooled by water. The material is added between the middle roll and the back roll. Since the three rollers rotate in different directions (the rotational speed increases sequentially from the back to the front), a good grinding action is produced. After the material is ground, it is scraped off by a scraper placed in front of the front roller.

Usually, the roller material of the three-roll mill is centrifugally cast from chilled-hard alloy cast iron, and the surface hardness is above HS70°; the diameter of the roller is highly precision ground, precise and delicate, and the grinding fineness of the material can reach 15μm. Left and right, so it can produce even and fine high quality products

Advantage

Triple roll mill is suitable for continuous processes. Extremely uniform dispersion is obtained.