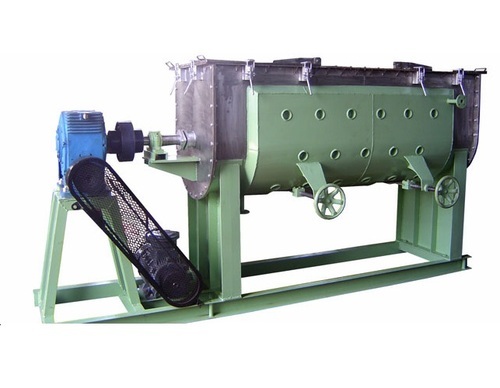

Description of Jacketed Ribbon Blender

Jacketed Ribbon Blender used from lab model to heavy model for batch or continuous flow form to achieve a homogeneous blend of a wide range of materials. It is a widely used style of blender and can be found in the pharmaceutical, food, animal feeds, confectionery, chemicals, fertilizer, plastics, cosmetics, pigments and insecticides industries. It is suitable for the distribution of liquids, fragrances and slightly pasty components in micro dosages onto carriers with triple mixing action. Each Jacketed Ribbon Blender unit consists of a horizontally-mounted, ‘U’-shaped trough containing a double helix blender bar and a longitudinal shaft of twin-bladed construction. Material is introduced and mixed by means of an agitator. The resultant mixing is gentle but with good shear and imp action.

Usually mixers consist of U Trough, Solid Shaft, Rotor Design, Gear Box & Motor Torque selection.

Jacketed Ribbon blender Working Principal:

Ribbon Blenders Mixing of Phases can be accomplished and by which mass and heat transfer can be enhanced between phases mixing is a means whereby mixing of Phases

Application:

This Ribbon Blender can be used for, Powder to Powder, Powder to Granules, Powder to Liquid, Liquid to Liquid of Liquid to gas and Powder to Gas Ribbon blender Agitator Design is depending on Applications Agitator & Rotor Design Selection is decided by various factors Like Viscosity, nature of feed, Product Bulk density, Heat sensitivity of product nature of final output of product.

Ribbon blender use are various Industry and various applications:

- Mixing of Chemical Dyes, Food & Pharmaceutical, Nutraceutical Powder

- Cosmetic Industries, Agro Chemical Pesticide, Formulation Plant

- Construction chemical, All Reaction Batch Like Guar Gum, TKP, SMCA, CMC, CMS

Technical Specification :-

Abster can offer Horizontal Ribbon Blender Jacketed 50 liter to 10000 Liter Volume capacity

| Model | Working capacity liters |

Total Capacity/ liters |

OUTPUT RPM |

Total HP required APPROX |

| RB – 200 | 200 ltrs | 300 ltrs | 40-65 | 2 to 3 HP |

| RB – 300 | 300 ltrs | 400 ltrs | 40-65 | 3 to 5 HP |

| RB – 500 | 500 ltrs | 750 ltrs | 30-45 | 5 to 7.5 HP |

| RB – 1000 | 1000 ltrs | 1500 ltrs | 30-40 | 7.5 to 10 HP |

| RB – 1500 | 1500 ltrs | 2000 ltrs | 30-45 | 10 to 20 HP |

| RB – 2000 | 2000 ltrs | 2500 ltrs | 30-45 | 15 to 30 HP |

| RB – 2500 | 2500 ltrs | 3000 ltrs | 30-45 | 20 to 30 HP |

| RB – 3000 | 3000 ltrs | 3500 ltrs | 25-30 | 20 to 30 HP |

| RB – 4000 | 4000 LTR | 5000 LTR | 25-30 | 20 to 30 hp |

| RB – 5000 | 5000 LTR | 6000 LTR | 25-30 | 30 TO 40 HP |

| RB – 10000 | 10000 LTR | 12500 LTR | 20-30 | 40 TO 50 HP |

Supplier of different model type of blender and also manufacturing and supplying customize blender to client requirement.

ribbon blender mixing machine, horizontal ribbon blender, ribbon blender design drawing, industrial ribbon blender,

vertical ribbon blender, ribbon blender animation