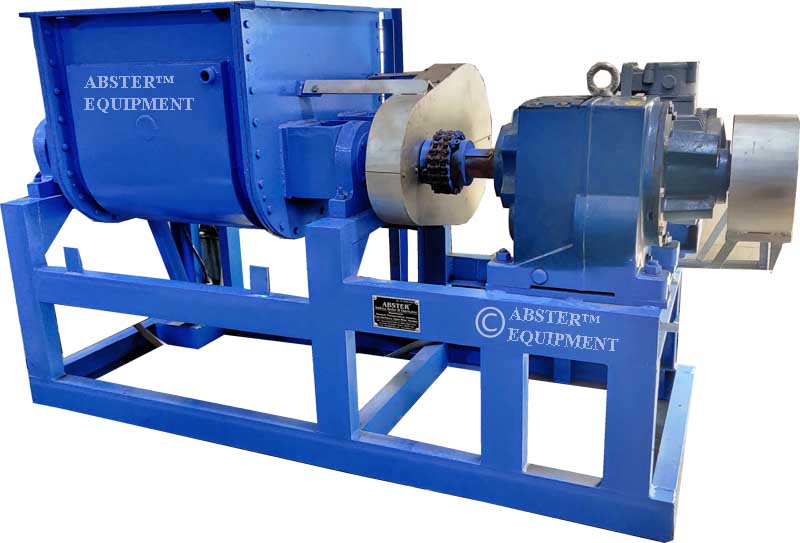

Sigma Kneader Mixer

Sigma Kneader Mixer

sigma kneader for dough/honey/chewing Gum high viscosity food mixing

Introductions

1 , Workiing Principle .

Kneader mainly including:Kneading Part,Machine Base,Hydraulic System,Drive System & Electrical Control System.

Hydraulic system is controlled by a set hydraulic station to operate hydro-cylinder including Tilting Dumping,Cover opening etc,it’s simple to operate & reliable.

Drive system mainly including Motor,Reducer & Gears.motor power mainly according to capacity of kneader.

2 , Heating:

Kneader can be designed to Heating & Unheated type.Heating way generallt is:Electric heating,Steam heating ,Thermal Oil heating.Cooling by water.

3 , Discharging way:

There are 3 main discharging way:Hydraulic Tilt Dumping,Bottom Valve Discharge & Extrusion screw discharging way.

Cylinder and blade part which contact product are made from SS 304 to assure product quality.

Feature

Generally machine adopt pass chassis which are convenient to install.

Reducer mainly adopt Helical need type or Hard tooth surface,to make machine with stable driving,small noise and long life time.

Mixing blade and inside of machine adopt SUS304 or SS316L,to insure produce purity

Shaft seal with advanced feature & good sealing effect

Electric Control Panel mainly including main engine drive,Hydraulic tilt dumping,Hydraulic open cover & Thermostatic control.

5,Main Type

Kneader mainly including Ordinal ,Pressure,Vacuum,High Temperature type.

6,material:

Carbon steel Kneader,Stainless steel Kneader & Special material kneader.

7,Discharging way:

Hydraulic Tilt dumping,Bottom valve discharging & Screw Extrusion discharge

8, capacity: 2-8000 Ltr

9,According to load:

Standard & Weighting strength type

10,Application

Main application : Chewing gum, Tooth paste, Plastic, Rubber, Silicone sealant, Dye, Color, Paint, Printing ink, Food Gum base. Carbon, High viscosity sealant, Glass glue, Silicone resin etc.

Also can be widly used in High viscosity, High elastic-plastic material’s mixing,kneading,crushing ,rejoining etc.