Centrifugal Sifter

For powder screening, classification, scalping, dust removal, with higher output and precision

CE ISO

Price:$900.00-$5,700.00/Set

Crush again Screening efficiency above 95%

No dust

Material:carbon steel/stainless steel

Feeding particle size: 40 mesh or less

Screen specification:80-530 mesh

Output: 1-10 tons/hour

Centrifugal Sifter

Centrifugal Sifter used For powder screening, classification, scalping, dust removal, with higher output and precision

For powder screening, classification, scalping, dust removal, with higher output and precision

CE ISO

Price:$900.00-$5,700.00/Set

Crush again Screening efficiency above 95%

No dust

Material:carbon steel/stainless steel

Feeding particle size: 40 mesh or less

Screen specification:80-530 mesh

Output: 1-10 tons/hour

Centrifugal Sifter Application: Ultra-fine powder with many fibers, high viscosity, light specific gravity and static electricity, such as heavy calcium powder, flour, hawthorn powder, traditional Ayurvedic and herbal powder, Spices, Foodstuff, medicine powder, graphite powder, rubber powder, etc.

What is Centrifugal Sifter?

Centrifugal sifter works on the principal of centrifugal force. The Rotary Sifter enables screening by pushing the product particles through the mesh using a screw conveyor or rotating paddles.

Centrifugal Sifter is used to screen a large amount of materials at high speed and more efficiently, allowing foreign matter to be separated from powder and particles, and used to sieving and sieving high-capacity powders or particles within 50-600 mesh,the output is 5-10 times of other sieves.

Function of Centrifugal Sifter

Centrifugal sifter has airflow feeding function, feeder crushing agglomerate function and airflow coarse screen function. Its advantage is that it saves customers the investment and operation and maintenance costs of the feeding machine, the life of the fine screen is extended by more than 10 times, and the output is stable. Improve the power consumption and reduce the quality of the finished powder through the network.

How Does Centrifugal Sifter Works?

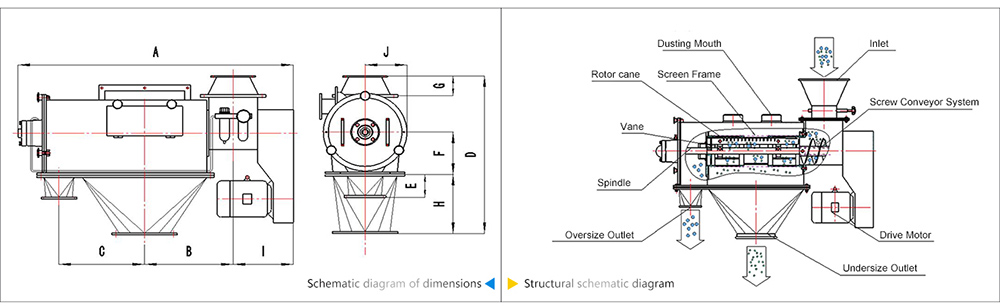

The material is fed into the centrifugal sifter inlet and accelerated by the auger. The auger moves the materials feeds the cylindrical sieve chamber, the material in the sieve chamber is collected by the sieve, the rotating blade/blade assembly and the push screen.The blades on the blade assembly are set in a spiral structure to move the material and screen the entire length of the screen at the optimal screening speed. It is suitable for any different application. The fine materials pass through the screen and are collected at the outlet of the main screen. / Or foreign materials are moved to the end of the screen chamber, after passing through the end baffle, and discharged through a separate smaller outlet.

Advantages of Centrifugal Sifter

1. High screening accuracy

Suitable for powders in the range of 80-530 mesh, especially suitable for screening fine powders, light specific gravity, easy to adhere to sticky powder or materials with electrostatic reaction.

2. No network blocking

The screen machine adopts fiber mesh to screen to avoid the phenomenon of electrostatic reaction, and can completely solve the problem that ordinary screens cannot screen.

3. High screening efficiency

The net can be automatically cleaned, and the agglomerated material can be re-crushed, and the screening efficiency can reach more than 95%

No dust

The entire screening cylinder can be sealed with a sealed isolation cover to avoid dust pollution of materials during the screening cycle.

Can work continuously

It can be used in single or multiple machines, flexible and convenient to move, long-term continuous operation, safe and reliable.

Centrifugal Sifter Specifications

| Model | A | B | C | D | E | F | G | H | I | J |

| TS18-65 | 1430 | 460 | 420 | 1005 | 135 | 230 | 250 | 330 | 340 | 210 |

| TS30-100 | 1845 | 655 | 766 | 1240 | 320 | 285 | 300 | 350 | 380 | 290 |

| TS50-130 | 2230 | 870 | 790 | 1775 | 280 | 515 | 150 | 660 | 400 | 485 |

| Model | Material | Power | Application |

| TS18-65 | Q235A | 2.2KW | Screening below 500 mesh |

| SUW304 | |||

| TS30-100 | Q235A | 4KW | |

| SUW304 | |||

| TS50-130 | Q235A | 5.5KW | |

| SUW304 |

Application of Centrifugal Sifter

Centrifugal sifter is widely used in all kinds of difficult-to-sieve fine powders, and fine powders in the range of 50-500 mesh can be sieved well. Such as light calcium powder, active calcium powder, active carbon powder, starch, Indian Medicine powder, Ayurveda powder, Chinese medicine powder, fly ash, zinc powder, graphite powder, quartz sand powder, gold powder, clay powder, hawthorn powder, fruit thinning powder, calcium hydroxide powder, pesticides Powder, konjac powder, fluorescent powder, wood powder, flour, epoxy resin powder, manganese dioxide, sulfur powder, alumina powder, Bakelite powder, magnesium oxide, perlite powder, iron powder, ventrifugal sifter is a kind of mesh sieve Sorting and grading equipment, not a flour mill. The pulverizing function of the feeder only breaks the agglomerated powder to facilitate the netting, and has no grinding function. Therefore, when selecting centrifugal sifter to screen fine powder of a certain fineness, you must first know what proportion of the fine powder is contained in it. If the fineness is only 200 mesh, it is not necessary to sift out fine powder of 325 mesh. possible. The characteristic of Centrifugal sifter Centrifugal sifter is that the sieve is fine but not coarse, and the bulk and granular materials are suitable for classification with a vibrating sieve.

Centrifugal Sifter Specifications

T

| Model | A | B | C | D | E | F | G | H | I | J |

| TS18-65 | 1430 | 460 | 420 | 1005 | 135 | 230 | 250 | 330 | 340 | 210 |

| TS30-100 | 1845 | 655 | 766 | 1240 | 320 | 285 | 300 | 350 | 380 | 290 |

| TS50-130 | 2230 | 870 | 790 | 1775 | 280 | 515 | 150 | 660 | 400 | 485 |

Our other powder Processing Equipment:

Octagonal Blender, Ribbon Blender, multi Mill, Double Cone Blender, Vibro Sifter working principle