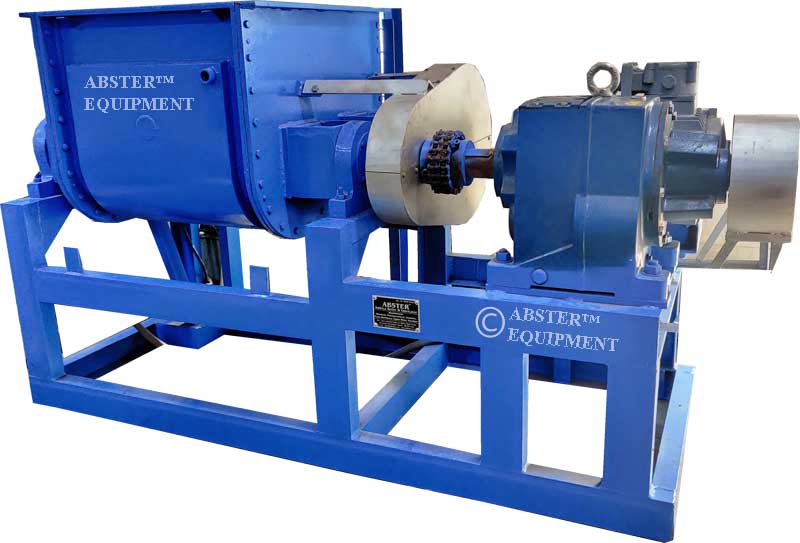

Bubble gum sigma mixer

Chewing gum sigma mixer manufacturer

Z blade Sigma Mixer

Application and introduction Chewing Gum Sigma Mixer is an widely used mixing machine ,with strong mixing blade and motor ,mainly for high viscous materials and slurries, It with special Z blade ,and a U shape chamber with cover , Two blade rotating with different speed ,one is slow and one is quick

Bubble Gum Sigma Mixer Kneading Mixer Kneader

Application and introduction

Sigma mixer is an widely used mixing machine ,with strong mixing blade and motor ,mainly for high viscous materials and slurries, It with special Z blade ,and a U shape chamber with cover , Two blade rotating with different speed ,one is slow and one is quick.

two speed producing an high forced power to the materials to make the materials well mixed and stable uniformed.

The sigma blade mixer is widely used on many areas which are suitable for hard and high viscous materials .like food industry ,plastic .,rubber ,and chemicals.

Bubble gum chewing gum sigma mixer is an very necessary equipment for bubble gum and chewing gum

production ,It is working with high efficiency and low energy cost . and vacuum system and screw extruder device is guaranteed the quality and purify.

Chewing Gum Sigma Mixer Specification

Model Capacity (L) Power (kw) Rotating speed rpm Vacuum degree( Mpa) Weight Jacket

ABFSM-5 5 0.75 33/23 -0.094 300 Customized

ABFSM-10 10 1.1 33/23 -0.094 400 Customized

ABFSM-50 50 3 45/23 -0.094 600 Customized

ABFSM-100 100 7.5 35/22 -0.094 1200 Customized

ABFSM-300 300 11-30 37/21 -0.094 1600 Customized

ABFSM-500 500 15-37 35/25 -0.094 3000 Customized

ABFSM-1000 1000 22-90 35/25 -0.094 4500 Customized

ABFSM-1500 1500 22-90 30-16 -0.094 5800 Customized

ABFSM-2000 2000 30-110 30/16 -0.094 6000 Customized

Salient Features

Sigma Mixer machine is a Batch type Mixer

In sigma mixer, Mixing Trough and Blades are fabricated from mild steel, stainless steel 304 and 316 grade.

Blades of sigma mixers are designed to obtain thorough mixing of high viscosity materials.

Sigma Mixers Blades are machined to keep minimum equal gap between through walls and blades.

Sigma mixers have fixed with Heavy-duty gears to sustain of load of Kneading.

Shaft sealing into the stuffing boxes is provided by Teflon Chevron Rings / PTFE breaded gland rope to prevent leaking from blade ends.

Safety Guards and Grills are provided for maximum safety in sigma mixers.

chewing gum sigma mixer, sigma mixer, mixing machine with strong mixing