How to choose Ribbon blender powder mixer

1. Select the horizontal ribbon mixer according to the daily production volume. Because the processing time of each batch of materials in the mixer is about 10 minutes, plus the time of discharging and feeding, the processing time of each batch of materials can be calculated as 15 minutes, then 4 batches of materials can be processed continuously in 1 hour. If you choose a mixer with a processing capacity of 100 kg per batch, you can process 400 kg per hour. Users can choose the horizontal mixer according to their needs.

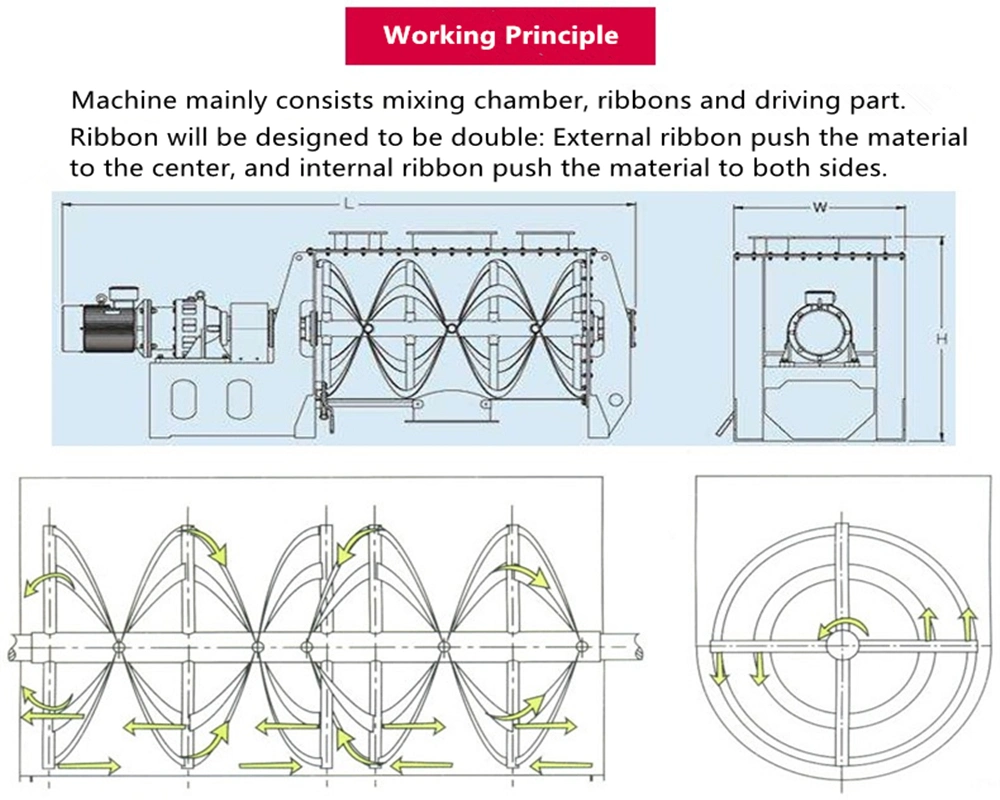

Ribbon Blender Working Principle

2. According to the working principle of the horizontal ribbon blender mixer, the ability of the double ribbon belt for mixing to push materials in the opposite direction should be basically the same. Since the pitch of the inner spiral belt is equal to that of the outer spiral belt, in order to achieve the same ability to push materials, the width of the inner spiral belt should be larger than that of the outer spiral belt, otherwise the materials will be concentrated in one direction. Therefore, pay attention to this when choosing a horizontal mixer.

3. According to the design principle, the gap between the ribbon blade and the shell in the ribbon blade mixer can be 4 mm to 10 mm, and the materials can be driven to participate in the mixing by friction. However, due to the different crushing particle size and the friction coefficient of the materials, the mixing time of the materials of various components will be different, resulting in non-uniformity of the product. Some manufacturers have realized this and made improvements to their products. One is to pay attention to the machining accuracy, so that the bottom gap is reduced to about 3 mm; the other is to make the position between the main shaft and the housing into an adjustable form, according to the amount of wear can often adjust the gap between the ribbon belt and the housing . When choosing a mixer, these two forms of products should be the best choice.

4. Pay attention to the discharge type when selecting the horizontal ribbon mixer. Communicate with the supplier in a timely manner to choose the valve form suitable for your process, and at the same time do not choose the discharge form of the side port. The reason is: when the mixer finishes mixing in the specified time, it can be cleaned once in the shortest time to ensure the uniformity of the material; if it is gradually cleared with the side mouth spiral belt, one will delay the time and the expected productivity will not be achieved, and the other is The material has already reached the best uniformity. Excessive stirring will cause the material to segregate and destroy the uniformity, thus losing the meaning of selecting a horizontal ribbon type mixer.

5. Pay attention to the feeding sequence when using the horizontal ribbon mixer. Generally, large materials such as corn meal and soybean meal are added first, followed by small components such as premix. Note that the premix must not be fed by a screw elevator, and a one-time dumping feed should be used, or manual feeding, so as to avoid the segregation and loss of active ingredients in the premix.

6. When using a horizontal ribbon mixer, batch feeding should be done after the mixer is started. Don’t stop the machine at the end of the mixing and unload. Mix a batch after the net material is discharged. If it is restarted after full load, it will cause too much power and burn the motor.

Those are the key point of how to choose the ribbon mixer machine and we Abster Equipment would like to keep our professional to discuss with you based on your production process .And finally to recommend the right machine for you , For more informations ,please visit our website or contact us directly .